There are many reasons your business might need unique plastic bottles. When you're looking

for plastic bottles for sale in Sydney, work with Ant Packaging. We can help you design

plastic bottles up to one litre in volume and of any shape to use for your business.

Whether you manufacture cosmetics, sell essential oils or work with another type of product, we can help

you design a bottle that works.

Designing Unique Plastic Bottles

No matter what stage of development your project is in, we can help you to design a bottling system that

works for your unique needs and products. We understand that you need to stick to a budget and a timeline, so

we'll work with you to design plastic bottles that fit your needs and can be manufactured quickly and

inexpensively.

No matter what stage of development your project is in, we can help you to design a bottling system that

works for your unique needs and products. We understand that you need to stick to a budget and a timeline, so

we'll work with you to design plastic bottles that fit your needs and can be manufactured quickly and

inexpensively.

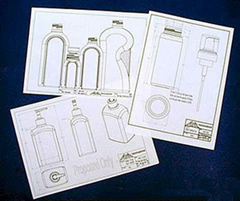

When you come to see us, bring an idea of what you need. Even if all you have is a simple sketch, we can

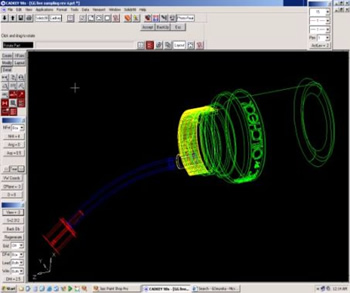

use that as a starting point. We utilise computer-aided design (CAD) software to develop line

drawings and 3D models of the plastic bottles you want.

Utilizing Rapid Prototyping

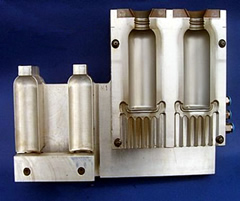

When you work with bottle suppliers like Ant Packaging, you can get a physical prototype of your

plastic products in record time. We utilise stereolithography, a rapid prototyping process that allows us to

produce an intricate prototype of your product. These prototypes are made of photo-sensitive resin and can be

used for marketing purposes.

If we cannot manufacture your prototypes in this way, we can use silicon tooling to mould parts

instead. We can manufacture from 10 to 100 parts with silicon tooling so you can get a good idea of how your

design works.

When you work with bottle suppliers like Ant Packaging, you can get a physical prototype of your

plastic products in record time. We utilise stereolithography, a rapid prototyping process that allows us to

produce an intricate prototype of your product. These prototypes are made of photo-sensitive resin and can be

used for marketing purposes.

If we cannot manufacture your prototypes in this way, we can use silicon tooling to mould parts

instead. We can manufacture from 10 to 100 parts with silicon tooling so you can get a good idea of how your

design works.

Once you're satisfied with the prototypes, we move onto the final tooling process. We are committed to

providing our customers with the best product in the time that they need it and with no unexpected surprises.

Your satisfaction is our priority.

Browse our products or give

us a call to design unique bottles for your business. You can reach us on +61 2 6687

1455, or you can fill out our contact request form. We work with customers

across Australia, so don't hesitate to contact us.